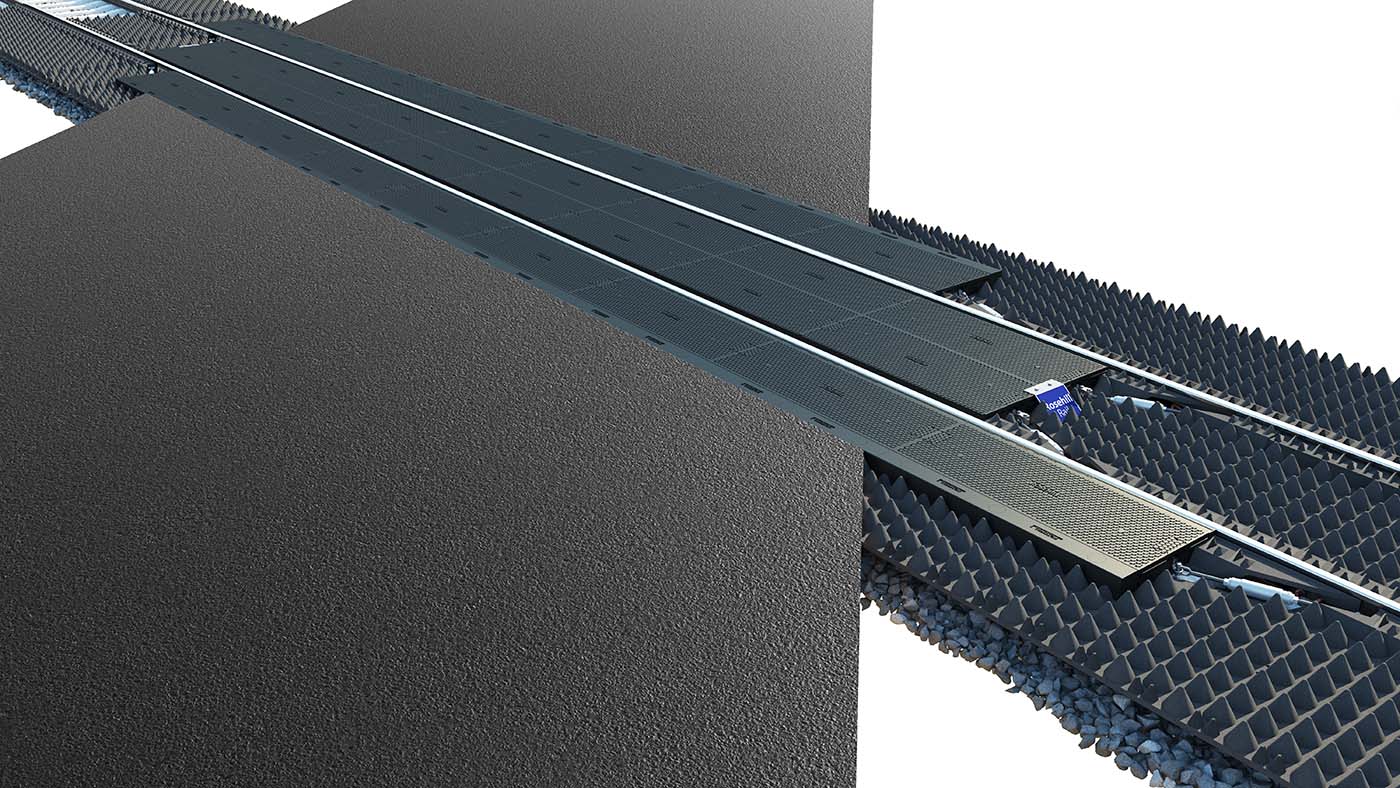

LINK System

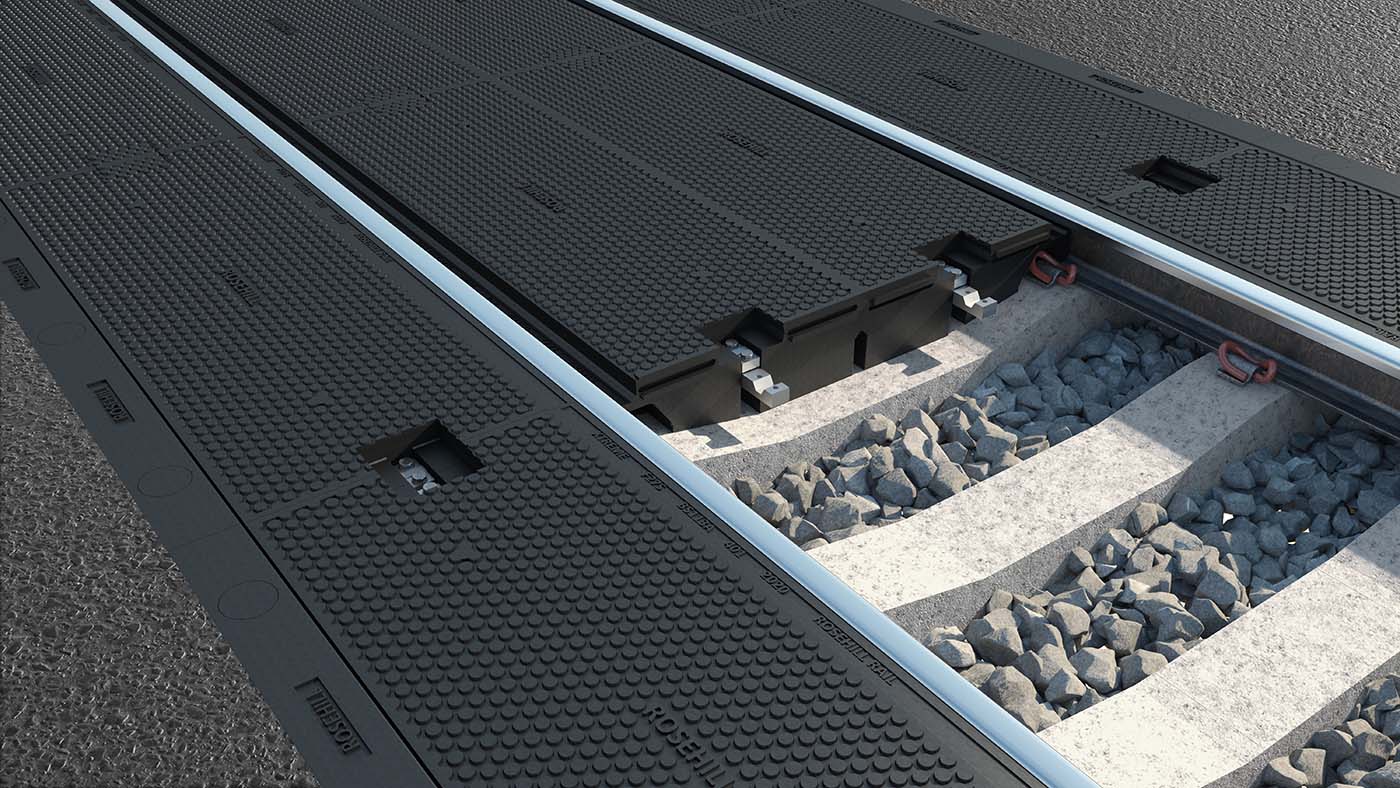

The LINK System accommodates horizontal movement during track loading, preventing panel separation whilst maintaining structural integrity.

Each panel is manufactured under compression using recycled rubber and Rosehill’s proprietary polyurethane chemistry, ensuring long-term dimensional stability.

LINK System Overview

- NEW moulded rubber tongue and groove connections

- Horizontal linking system

- Compression-manufactured panels

- Universal gauge compatibility

- Full rail profile adaptability

- Modular construction

- Compatible with 600mm sleeper centres

- Single matrix containment system

- Integrated rubber edge beam options

- Prevents vertical lift and panel separation

- Manages dynamic loading effects

- Maintains dimensional stability

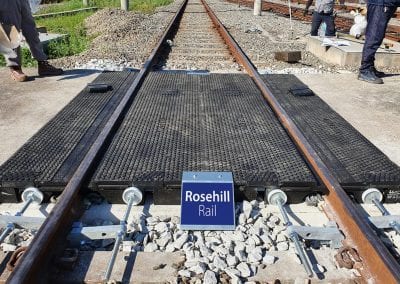

- Reduces installation time

- Minimises track possession requirements

- Enables selective panel replacement

- Lowers maintenance costs

- Improves crossing durability

- Enhances safety performance

Please take a few minutes to read through the installation and maintenance PDF as it will save you valuable time during installation.

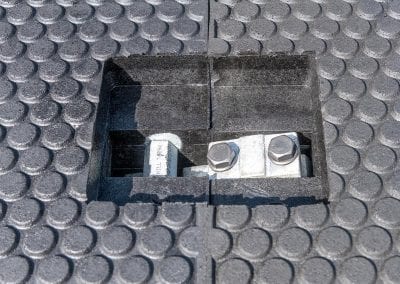

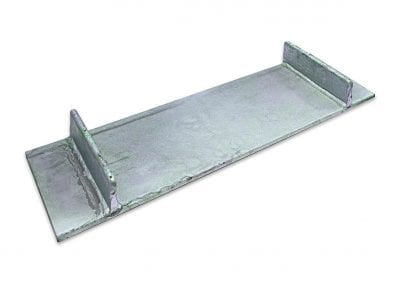

Speed of installations and removals can be further improved using Rosehill Rail Lifting Pins. The two holes are then simply filled in with a rubber plug.

The fixing cavity is filled in with a cover plate.