Modular Drainage System

The Rosehill Rail Modular Drainage System (MDS) revolutionises rail drainage by replacing traditional perforated pipes and concrete systems with an innovative, sustainable solution.

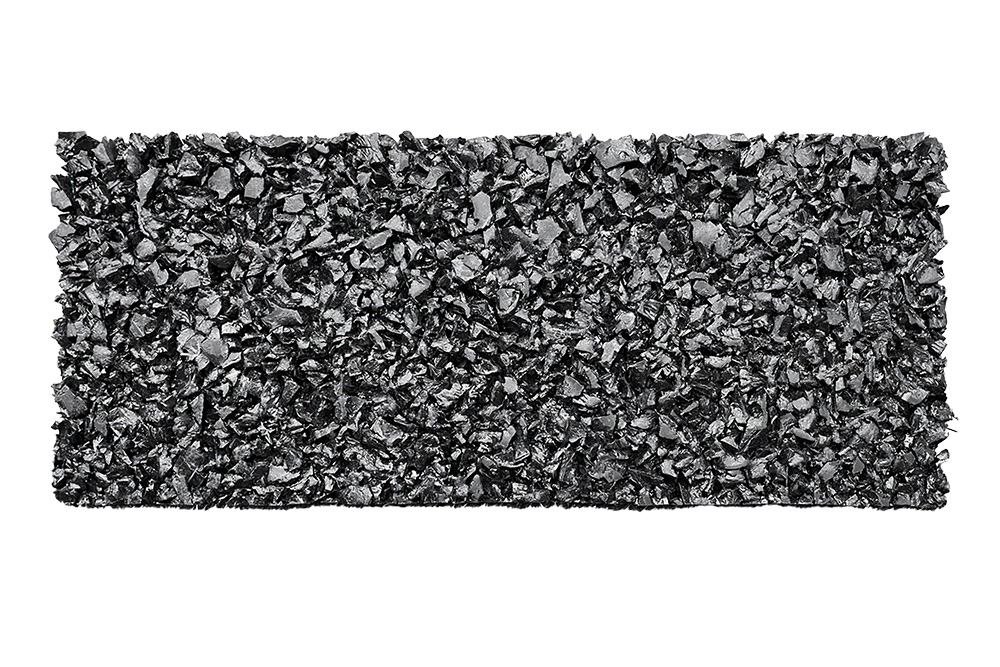

Manufactured from recycled rubber and featuring 45% void space, the system ensures sustained high permeability across its entire installation.

Modular Drainage System Overview

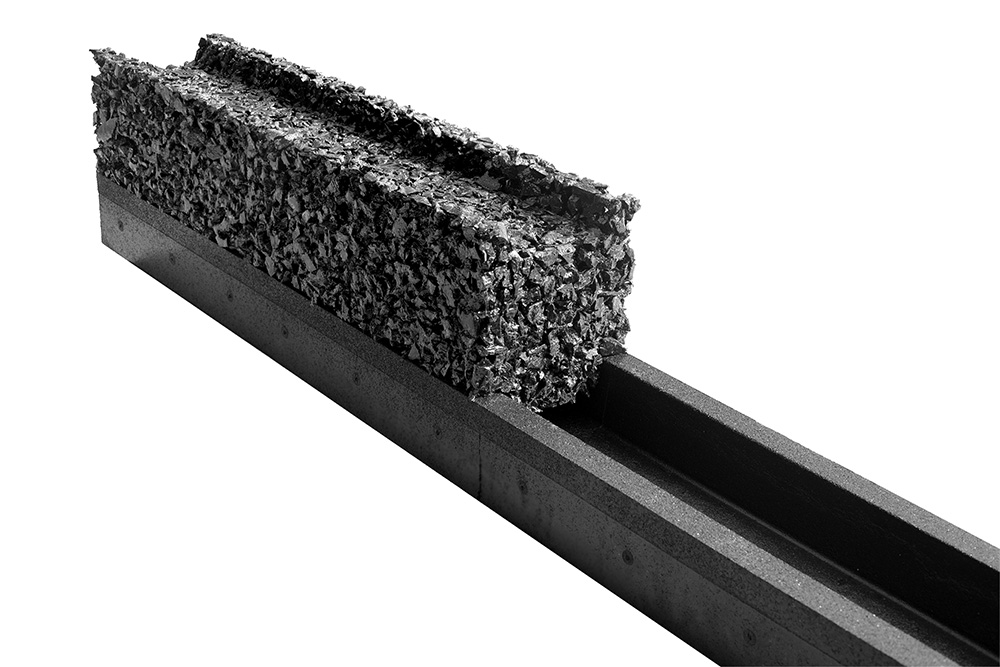

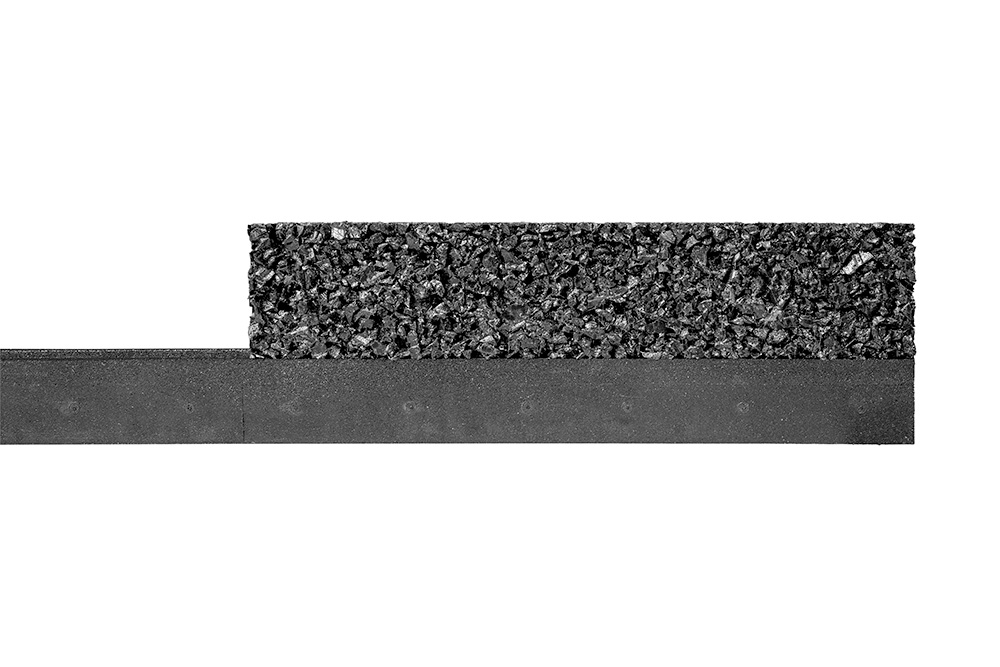

The Modular Drainage System (MDS) is a replacement for perforated pipe and/or perforated concrete within track drainage.

It provides sustained high permeability across its entire installation due to its 45% void space, effectively reducing and preventing surface and trapped water within the track ballast and formation.

Unlike perforated pipes and channels, which are prone to blockages and structural failures, the increased resilience and permanent voids within the MDS material and its structure significantly de-risks failure modes associated with poor or minimal maintenance, providing mitigation against the rapid deterioration and premature end of service life for rail assets.

Additionally, the MDS will self-correct installation misalignments, ensuring consistent, long-lasting drainage performance.

- Unique modular stacker and trough design

- 45% void ratio for optimal water flow

- Vertical permeability of 49 l/m²/s

- Horizontal flow capacity up to 12.6 l/s

- Self-correcting installation alignment

- Long-term load fatigue tested

- Chemical and temperature resistant

- Manufactured from recycled rubber

- Flexible ground movement accommodation

- UV resistant construction

- Enhanced infrastructure resilience

- Reduced maintenance requirements

- Diverts 9,250 tyres from landfill per kilometre

- Minimises track possession times

- Prevents track formation degradation

- Eliminates traditional drainage failure modes

- Lower whole-life costs

- Improved safety through water management

- Adaptable to all rail environments

- Extended 60+ year design life

System Overview

Technical Specification

Hydraulic Performance

Long Term Load Fatigue