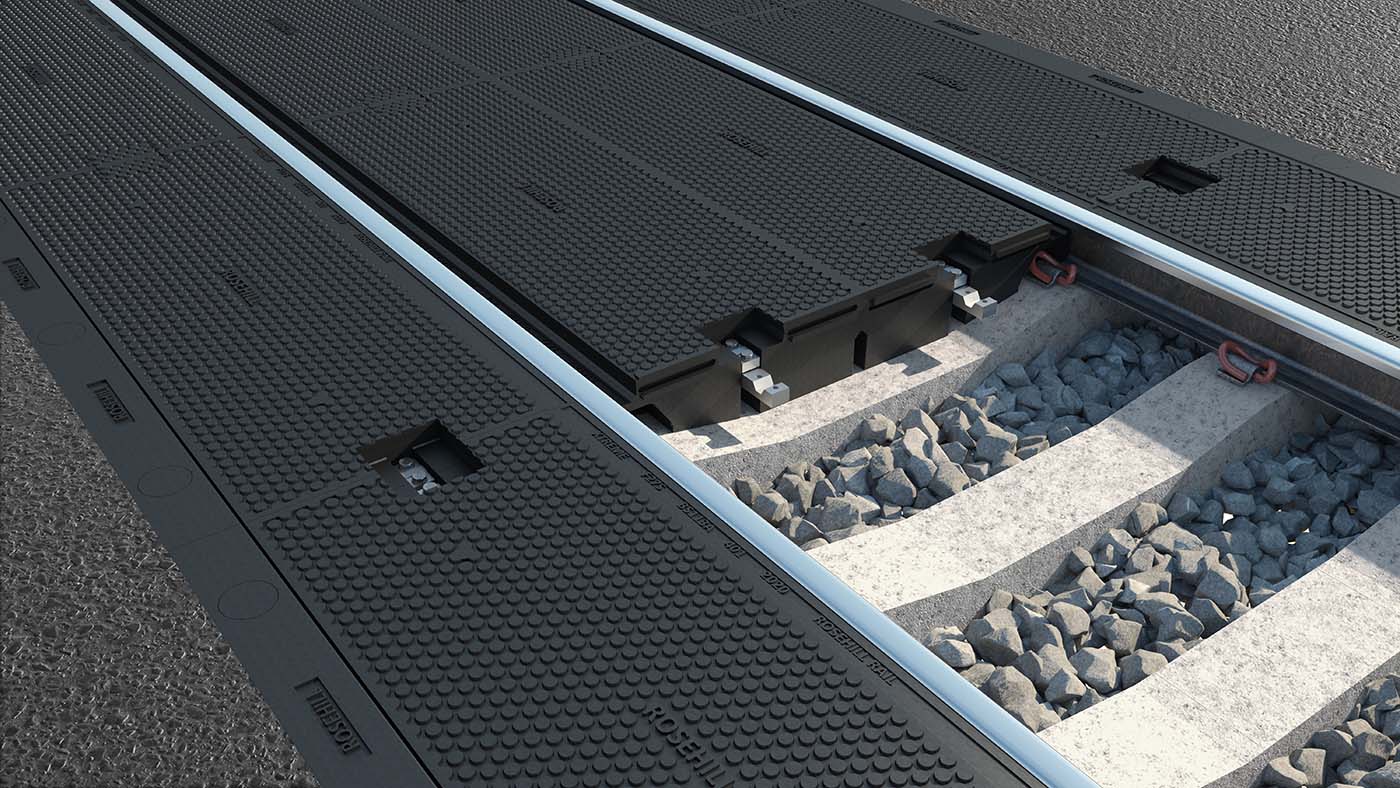

TITAN Heavy Duty System

TITAN is the ultimate heavy-duty system able to accommodate some of the world’s heaviest traffic, from articulated dumpers to multi-axle haul trucks and ballast tractors.

Designed for use in mining, construction, and other heavyweight industrial environments, Rosehill Rail’s exclusive cold cure moulding process and unique polyurethane chemistry means TITAN panels have a surface deflection of rubber but the strength of steel.

TITAN System Overview

- Individual panels are manufactured under compression to ensure dimensional stability and to combat Compressive Set

- By avoiding Compressive Set the panels provide stability to prevent distortion and gapping

- Additional performance enhancements include the NEW moulded rubber Tongue and Groove connections to secure against vertical lift

- For Sleeper centres at 600mm

- Panels can be manufactured for all Gauge Types

- Adapted for all Types of Rail, Clips and Sleepers

- Suitable for any situation, particularly long crossings and angled road intersections

- Additional performance enhancements include the NEW moulded rubber Tongue and Groove connections to secure against vertical lift.

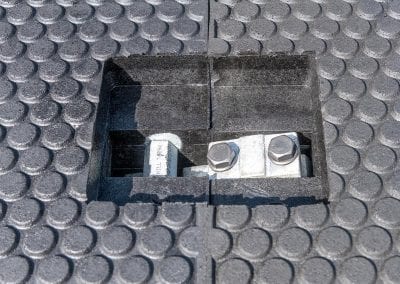

- Quick and simple installation and removal by means of the Connectors used to link the panels together.

- No Specific tools are required.

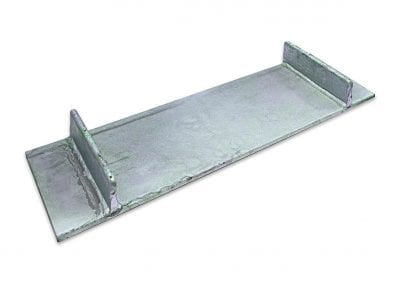

- The entire crossing is held in one matrix preventing panels becoming accidentally dislodged and held in place using the End Restraint.

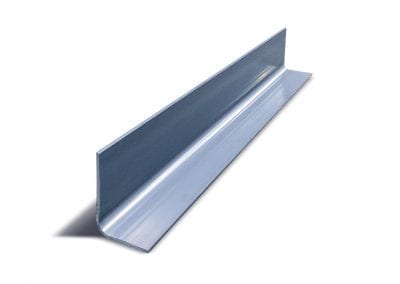

- It is recommended that the Panels sit on Rosehill Rail’s exclusive Rubber Edge Beam with wide outer panels.

Please take a few minutes to read through the installation and maintenance PDF as it will save you valuable time during installation.

Speed of installations and removals can be further improved using Rosehill Rail Lifting Pins. The two holes are then simply filled in with a Rubber Plug.

The fixing cavity is filled in with a Cover Plate.