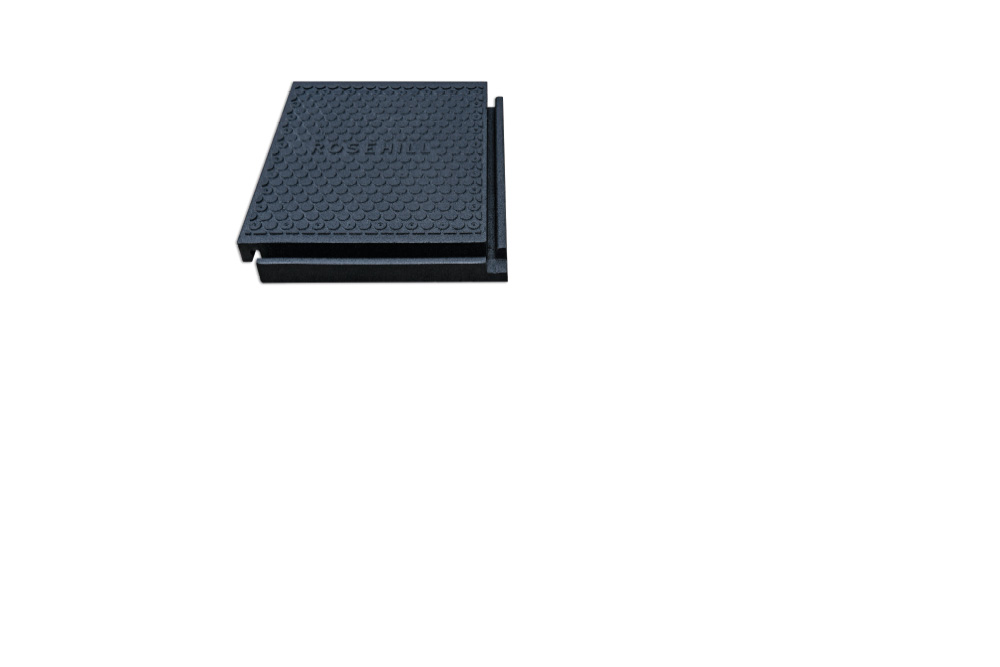

Walkway Panels

The Rosehill Walkway Panel offers a more secure, sustainable, and cost-effective alternative to traditional concrete paving blocks and aggregate footpaths.

With a design life exceeding 40 years and full reusability, these panels deliver both immediate and long-term environmental benefits.

Walkway Panel Overview

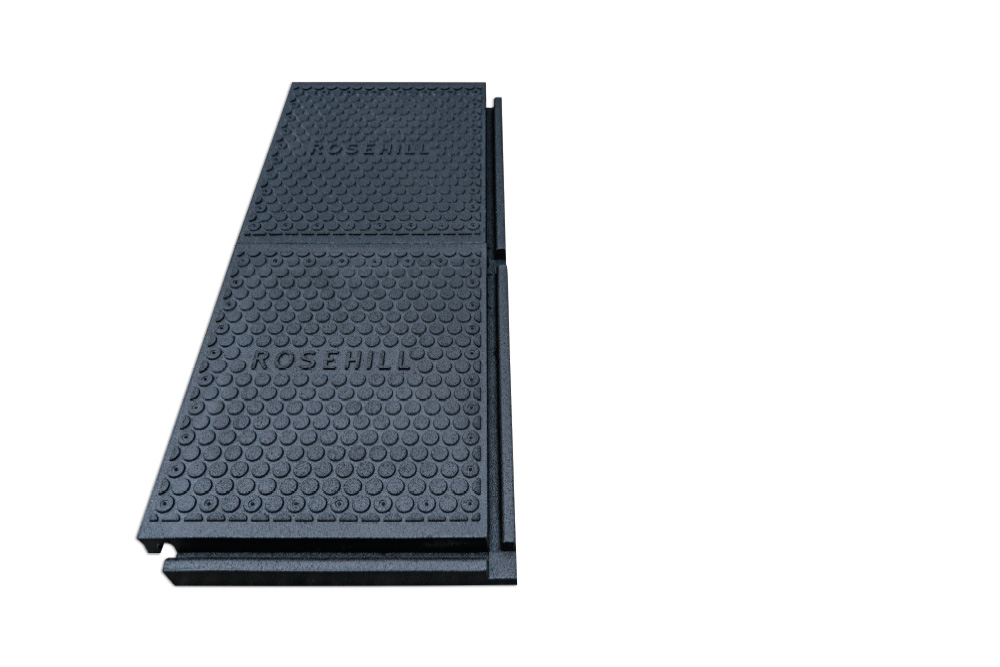

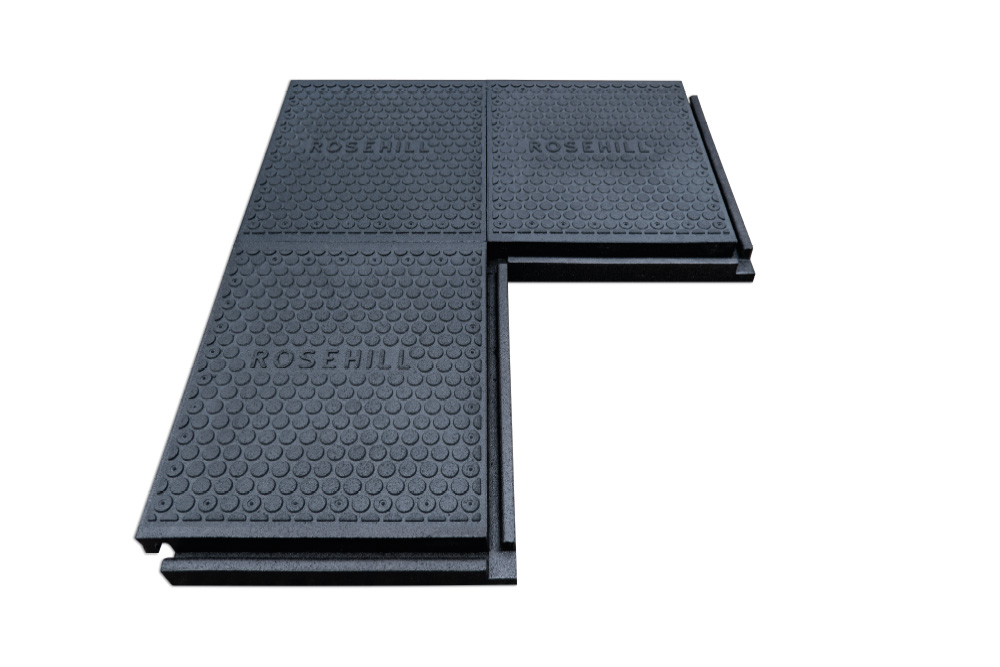

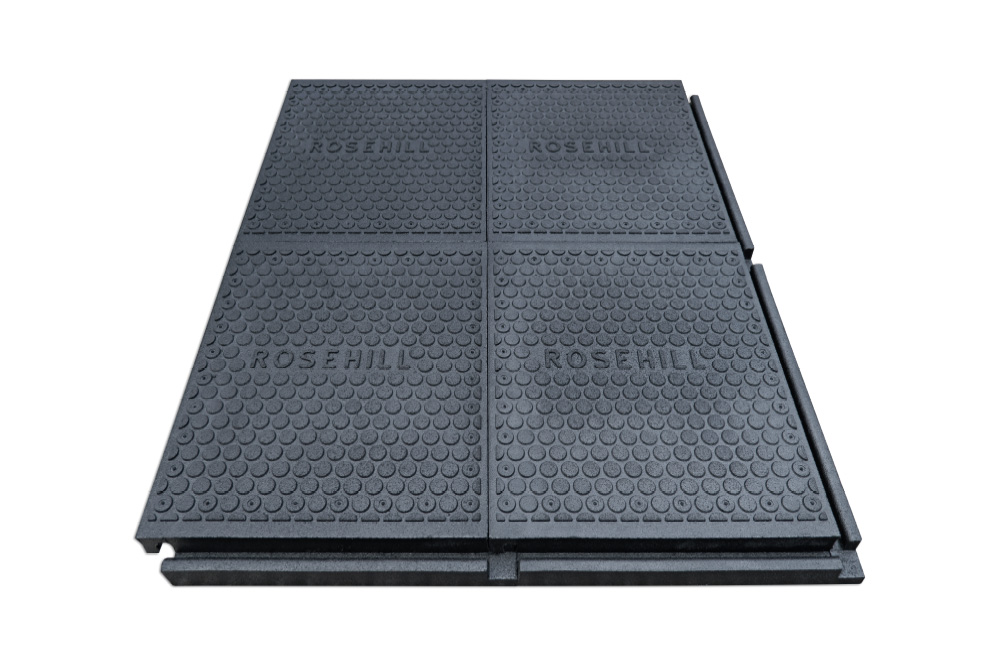

- 700mm x 500mm panel size

- Slip-resistant surface (PSV 45)

- Minimal ground preparation required

- Flexible installation options

- Weather-independent fitting

- Weed and rodent resistant design

- Modular construction system

- Recycled rubber composition

- Reduced carbon footprint versus concrete

- Quick and safe installation

- Minimal ongoing maintenance

- Enhanced worker safety

- Lower lifetime costs

- Improved access reliability

- Reduced environmental impact

- Extended service life

- Reusable and relocatable

Download the Walkway Panel brochure by clicking the link below: