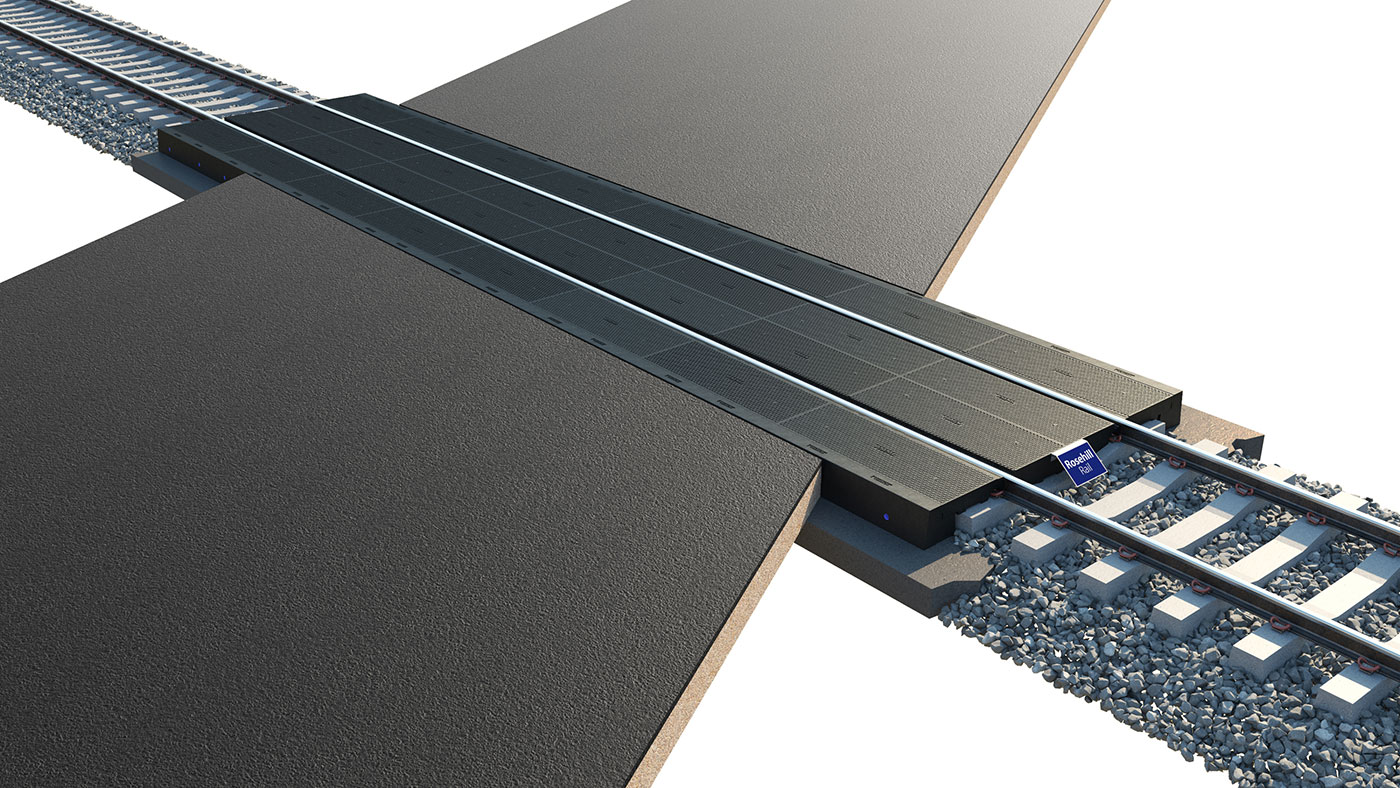

Baseplate System

The Rosehill Baseplate crossing system’s solid rubber panels can be cut to fit around fishplates, check rails (single and double), and turnouts.

Panels can also be manufactured to fit around tight curves, making them especially useful for tramway applications.

The system allows for very fast installation, is ideal for average sized crossings and is available in various grades to accommodate track access, depots, agricultural, and pedestrian applications.

Baseplate System Overview

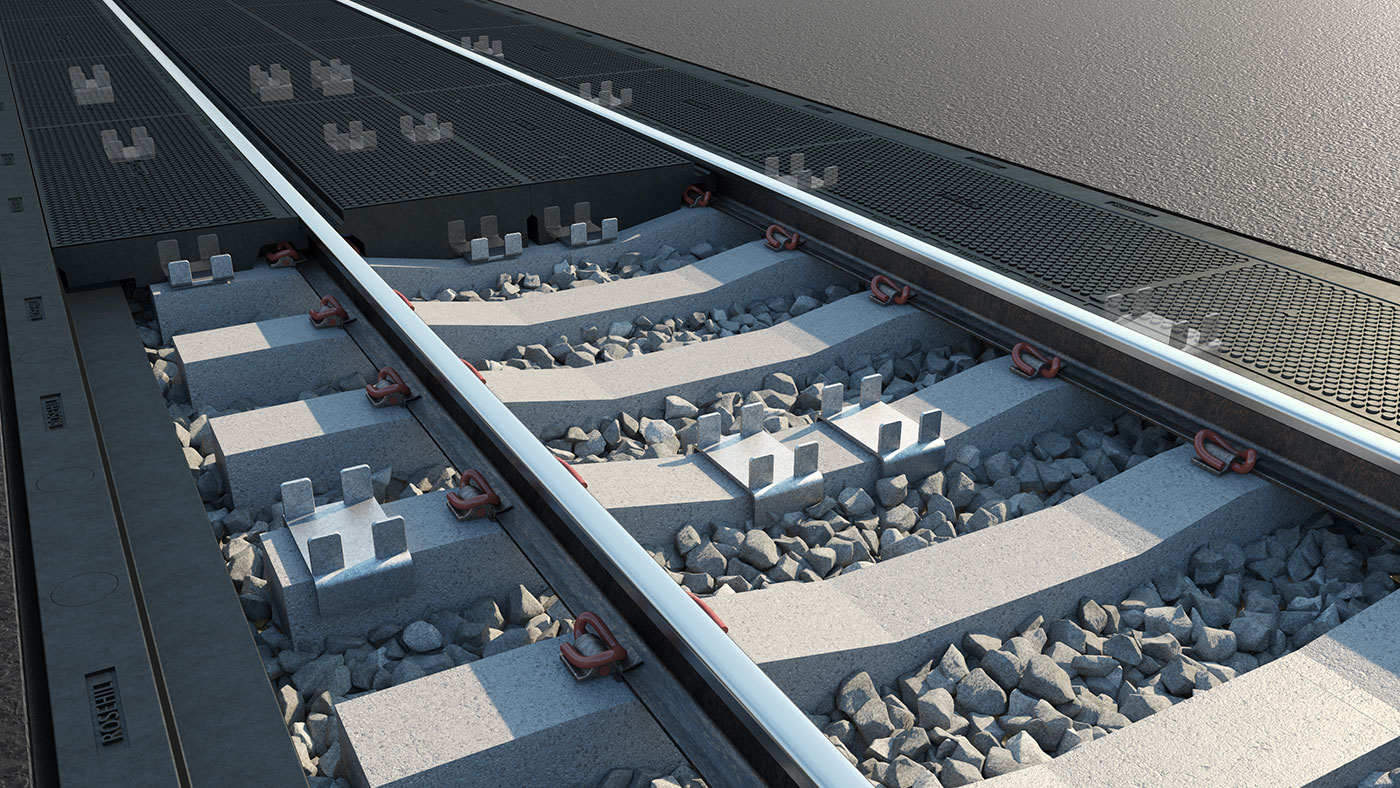

- Panels are manufactured to 1.8 meters long and as they are made from rubber they can be cut in half for shorter crossings.

- For sleeper centres at 600mm

- Panels can be manufactured for all gauge types

- Adapted for all types of rail, clips and sleepers

- Complies with anti-skid requirements.

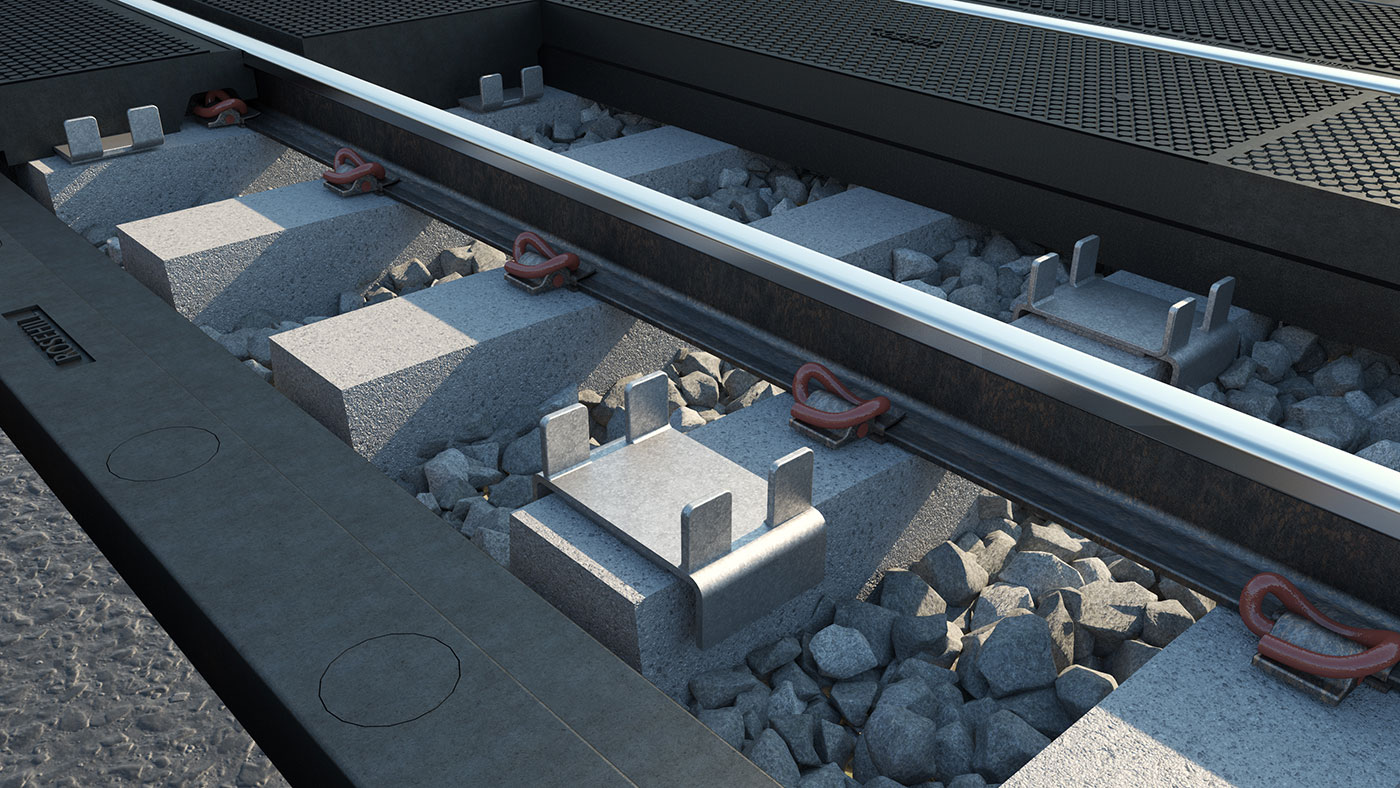

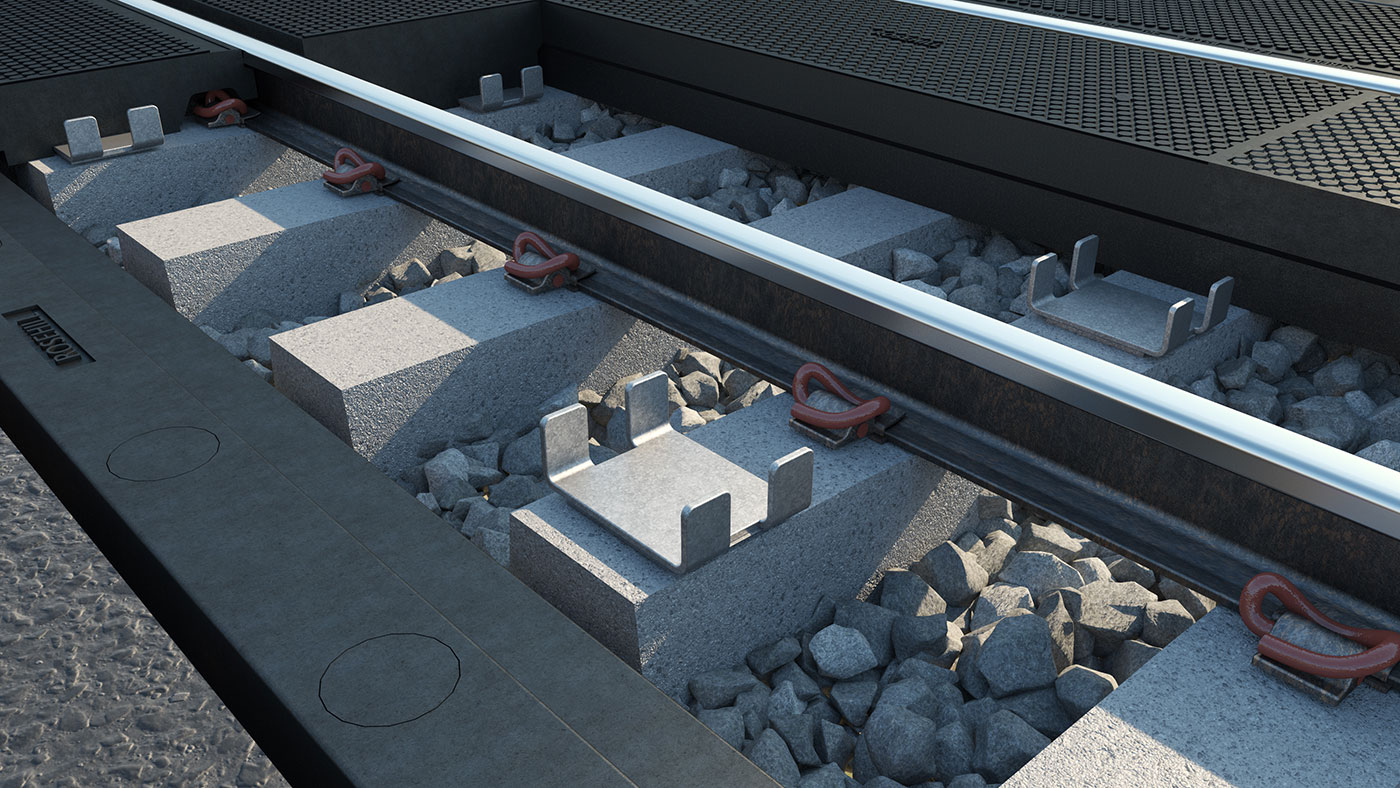

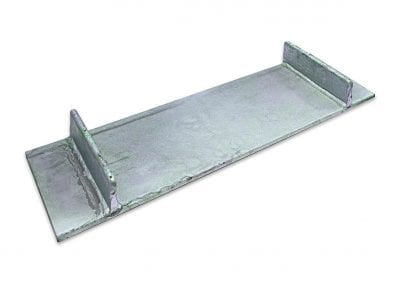

- Panels are extremely quick to install and remove using a simple baseplate which pulls the panels together

- No specific tools are required

- Panels can be modified for cut-to-fit installations

- Individual panels can be removed and placed without dislodging the neighbouring panel

- All types of Edge Beams can be accommodated

Please take a few minutes to read through the installation and maintenance PDF as it will save you valuable time during installation.

Speed of installations and removals can be further improved using Rosehill Rail Lifting Pins, the two holes are then simply filled in with a Rubber Plug.

We recommend that Winged Baseplates are used every three panels, with the remaining panels using Turret Baseplates.