Edge Beams

Manufactured from 100% recycled tyre rubber and bonded using cutting-edge cold cure technology, these beams offer significant weight savings whilst maintaining exceptional durability.

Edge Beam Overview

- Recycled rubber construction

- Cold cure bonding technology

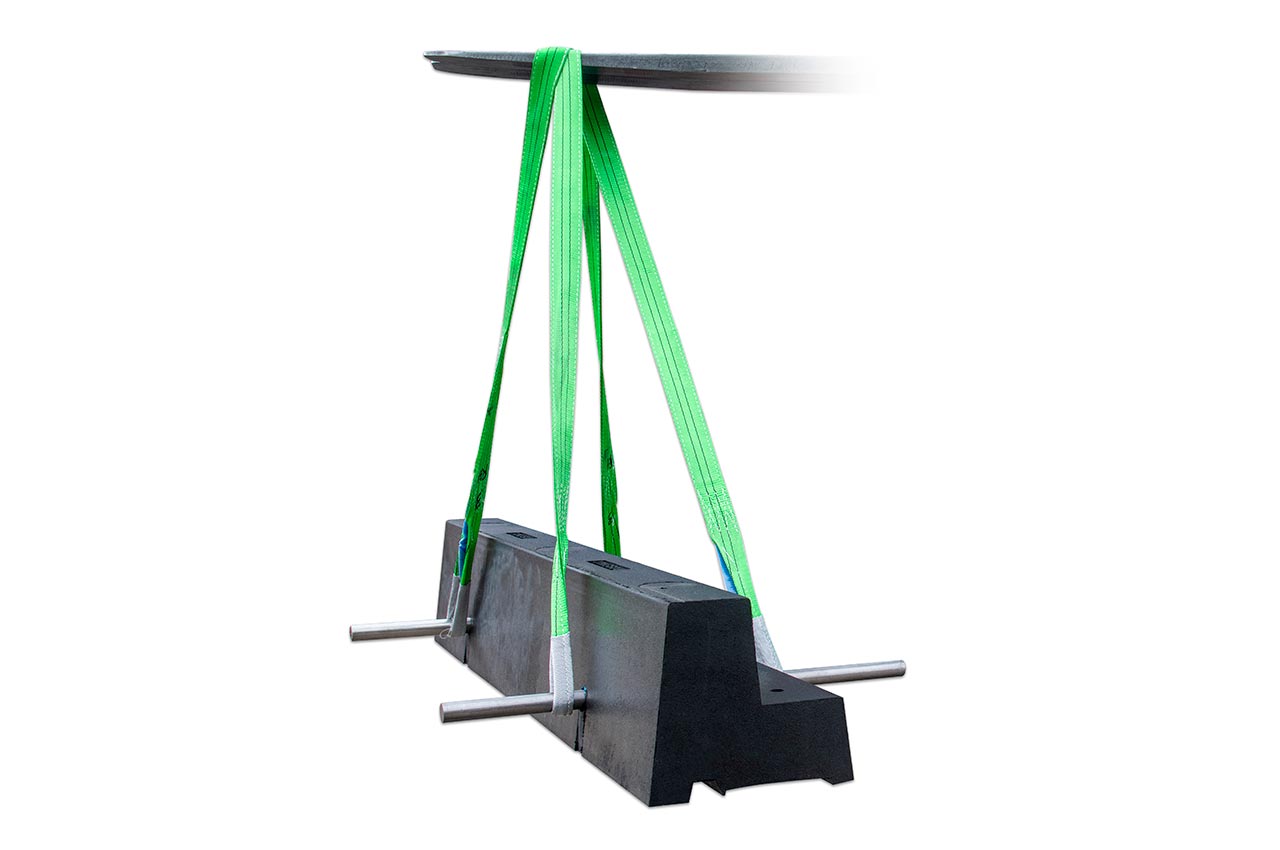

- Strategic lifting points

- 1.8-metre standard length

- Network Rail acceptance

- Compatible with all crossing systems

- Integrated drainage channels

- Non-spalling design

- Quick-fit installation system

- Significant weight reduction versus concrete

- Easier handling and installation

- Reduced installation time

- Lower transport costs

- No cracking or spalling

- Minimal maintenance requirements

- Enhanced crossing support

- Extended service life

- Improved sustainability credentials

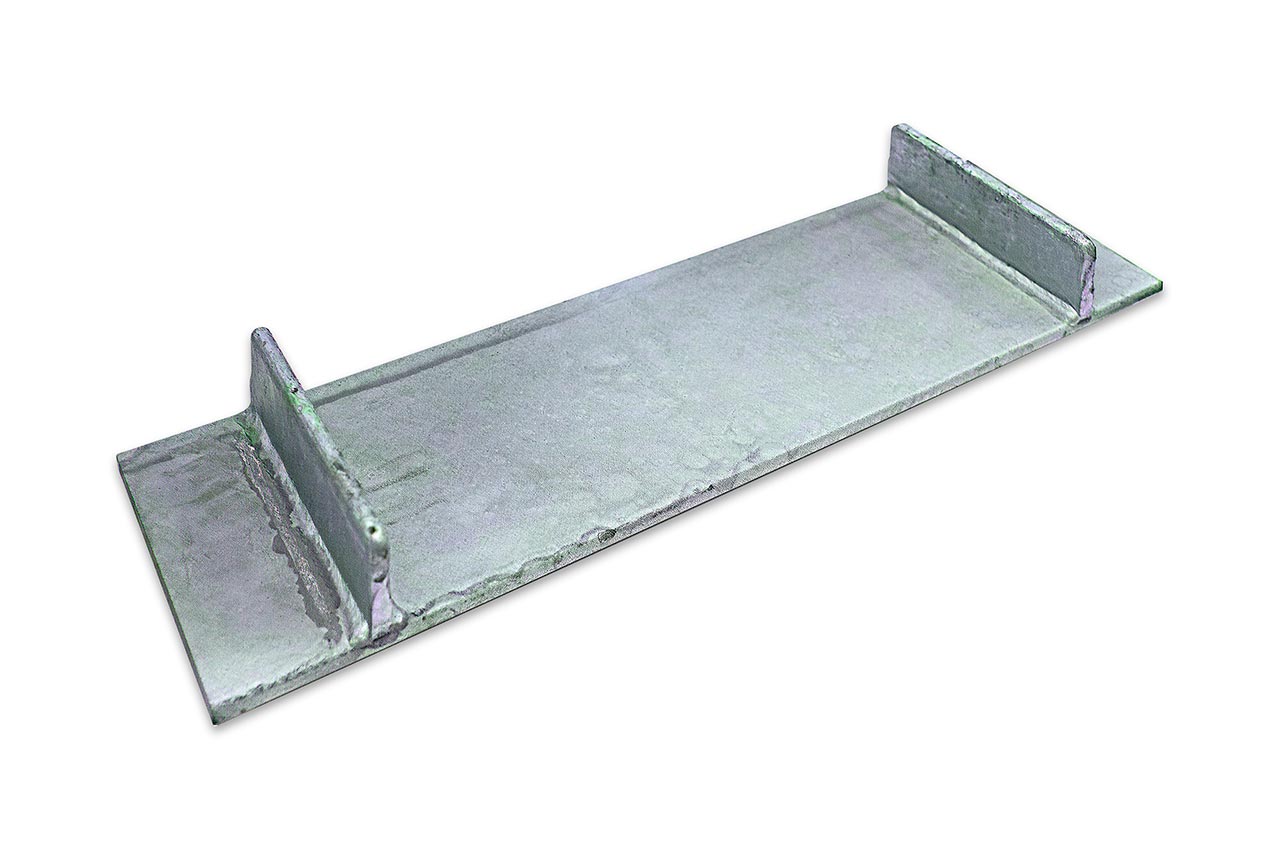

Steel and Plastic Edge Beams for Versatile Solutions

Rosehill Rail offers both steel and plastic edge beams to suit a variety of level crossing needs. Our steel edge beams provide maximum durability and strength, ideal for high-traffic areas where robustness is critical. They are designed to withstand the most demanding conditions and provide long-term stability, ensuring minimal wear even under constant load.

Our plastic edge beams are a lightweight, corrosion-resistant option that is perfect for installations requiring ease of handling and rapid deployment. Made from high-grade plastic materials, these beams offer excellent weather resistance, making them well-suited for applications where exposure to harsh conditions is expected.

Whether the project requires the exceptional durability of steel or the flexibility and ease of plastic, Rosehill Rail ensures that each solution delivers reliable, efficient performance tailored to specific site requirements.

This installation guide provides detailed instructions for correctly installing Rosehill’s rubber edge beams at level crossings. Designed to be a straightforward process, this guide ensures that you get the most from our durable, sustainable edge beams, achieving optimal performance and longevity.

Follow these step-by-step instructions to complete the installation safely and efficiently, ensuring your rail infrastructure benefits from the superior features of Rosehill’s rubber edge beams.